My Level 2 rocket is an extension and enhancement of my Level 1 rocket. Details of that rocket are on my Level 1 page.

| w/I211W (test flights) | w/J350W (cert. flight) | ||

| Name | Radio Flyer | ||

| Diameter | 10.2 cm (4 in) | ||

| Length | 192 cm (75.6 in) | ||

| Rail buttons | Two 1010 | ||

| Motor mount | 38 mm | ||

| Parachute (drogue) | 30.5 cm (12 in) nylon | ||

| Parachute (main) | 121.9 cm (48 in) nylon | ||

| Mass | 2992 g (no motor) | 3548 g | 3643 g |

| CP | 147 cm | ||

| CG (at launch) | 121 cm | 123 cm | |

| Caliber (at launch) | 2.6 | 2.3 | |

| Thrust-to-weight (end of rail) | 13.3 | 18.3 | |

| Speed at end of rail | 17.9 m/sec | 28.7 m/sec | |

| Apogee | 491 m | 877 m | |

| Vertical speed at landing | 7.7 m/sec | 7.8 m/sec | |

| OpenRocket file | ZephyrMRM-L2.zip |

I was very happy with the Apogee Zephyr kit and wanted to do dual deployment for my Level 2, so I ordered Apogee’s Dual Deployment Conversion Kit, which consists of an avionics bay, a drogue chute and protector, and an additional body tube to hold the main parachute. Another well thought out kit, although I was surprised they didn’t go with forged eye bolts. That was easily fixed, though.

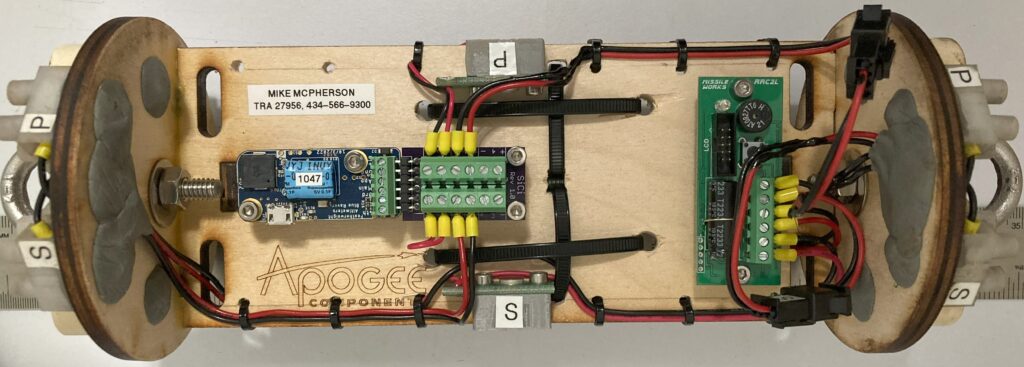

The avionics bay build was simple, so the avionics themselves were the main action for this build. I went with redundant flight computers from different manufacturers: primary is the Featherweight Blue Raven, secondary is the Missile Works RRC2L.

The Blue Raven is an amazingly capable device in a very small package. It can control four events, and collects a massive amount of data on each flight. Configuration and data download are via Bluetooth and a well-done smartphone app.

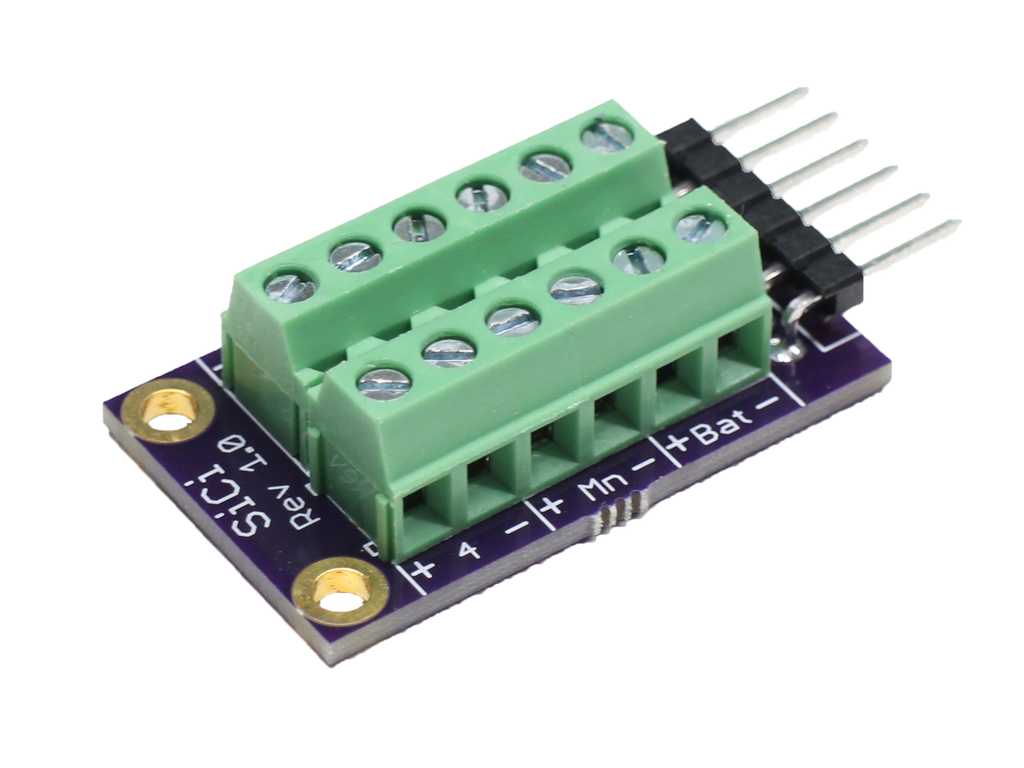

The terminal block on the Blue Raven is tiny, so I also ordered an Additive Aerospace Simple Circuit Terminal Expansion that brings the Blue Raven pins out to larger terminal blocks and in a more traditional layout.

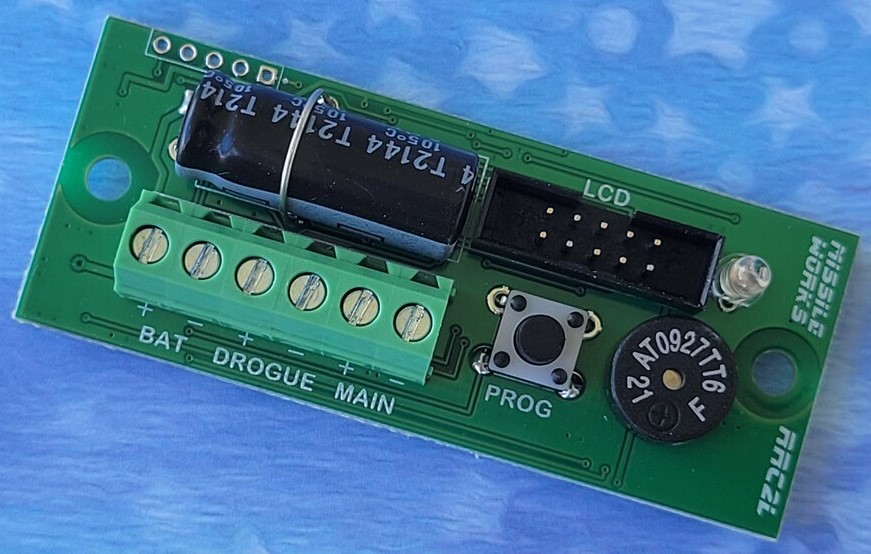

The RRC2L is a simpler altimeter with a very good reputation around here for reliability.

Everything is staked in the spirit of NASA-STD-8739.1B.

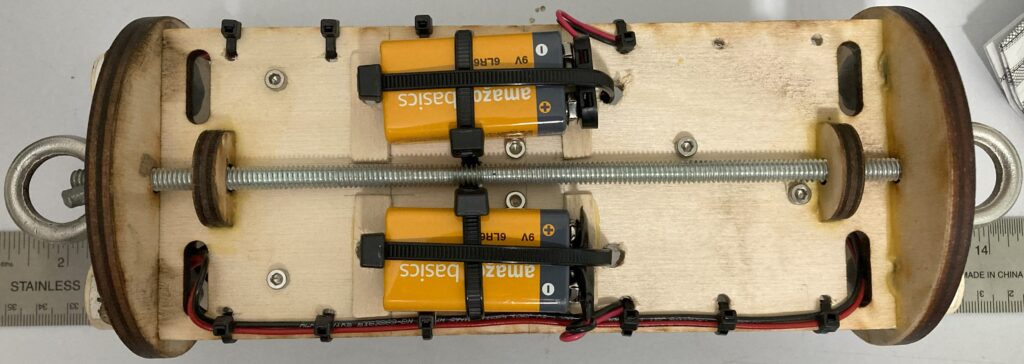

The batteries are secured by zip ties and wooden blocks glued to the sled. There is a very interesting article on the results of testing a bunch of 9V batteries at the Missile Works site: https://www.missileworks.com/9v-success.

Deployment test #1. There are three 2-56 nylon shear screws at each of the two separation points. The drogue is an 18″ nylon chute, main is a 58″ nylon chute. I used RockSim’s recommendation: 2.5 g for the drogue, 1.5 g for the main. The ejection test was exciting, too exciting! The nosecone remained attached after the drogue separation event, though. I’m going to try again with 2.0 g and 1.0 g. Also, some of the shear screws didn’t shear, they bent and pulled out of their holes. I’m going to reinforce the holes to try to get shearing.

Deployment test #2. Holes for shear screws resized and reinforced with CA. All the screws sheared perfectly this time. 2.0g of black powder turned out to be great for the drogue separation. I tried 1.0g for the main, but that wasn’t enough. 1.5g seems to be perfect. The only bad news is that I got the drogue in its Nomex protector too close to the ejection charge; the charge blew a few little holes through the Nomex and melted a few holes in the drogue. They can be easily patched, though. Next time, lots of dog barf!

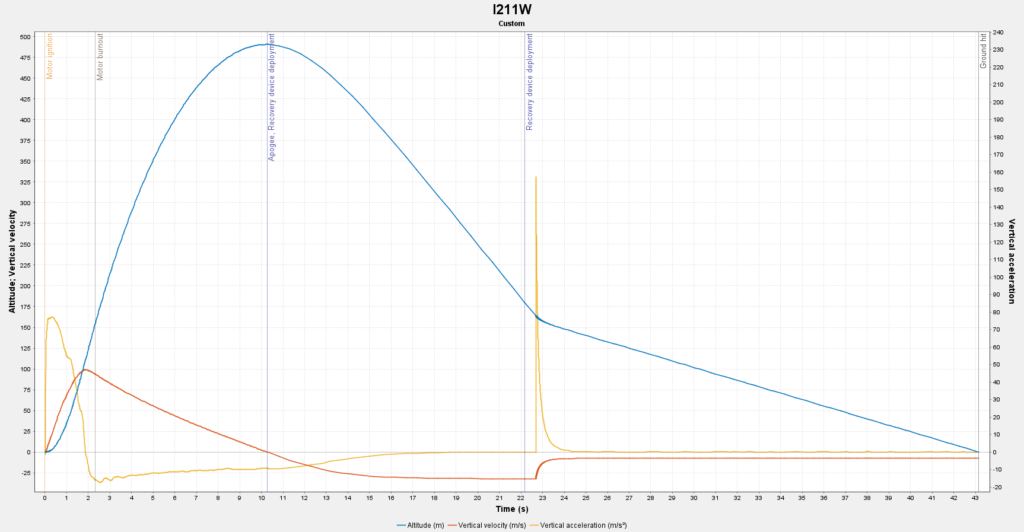

According to OpenRocket, the flight profile with an AeroTech I211W looks like:

And unlike my Level 1 rocket, this one I painted! I can’t take credit for the Radio Flyer logo, though. Turns out they sell spare parts for your little red wagon, including the logo.

Test flight #1, 14 July 2024, at the VAST Jack Mountain Village launch. The flight on an I211W was beautiful, the Blue Raven and RRC2L worked perfectly, and all four ejection charges went on schedule. The drogue deployed, but the main did not. Luckily, a gust of wind caused the lower body of the rocket to land on its side, so there was no damage from the landing. Flight data from the Blue Raven is at https://www.kq9p.us/wp-content/uploads/RadioFlyer-FlightData-14Jul2024.zip.

The problem turned out to be with the shear pins. One of the pins sheared, and the other two were partly sheared. They stuck between the nosecone and body tube and prevented the nosecone from separating. Apparently, during ground testing the holes in the body tube – which were reinforced with CA – had elongated enough to prevent the pins from shearing properly. All that pressure had to do something, though: it ripped out the three rivets securing the body tube to the avbay!

So, https://www.rocketryforum.com/threads/shear-pin-shear-plates-in-your-cardboard-tubes.136706/#post-1627875. I added three 5 mil copper shear plates to reinforce the holes in the body tube.

Test flight #2, 10 Aug 2024, at the VAST Jack Mountain Village launch. Again, the launch was on an I211W. The launch and flight were textbook, the avionics worked well, all four ejection charges fired, and the shear pins sheared cleanly. This time, the main deployed, but the drogue did not. This was operator error, though: I attached the drogue to the recovery harness too close to the body tube, so there wasn’t enough slack to pull out the drogue. Lesson learned. Flight data: https://www.kq9p.us/wp-content/uploads/RadioFlyer-FlightData-10Aug2024.zip.

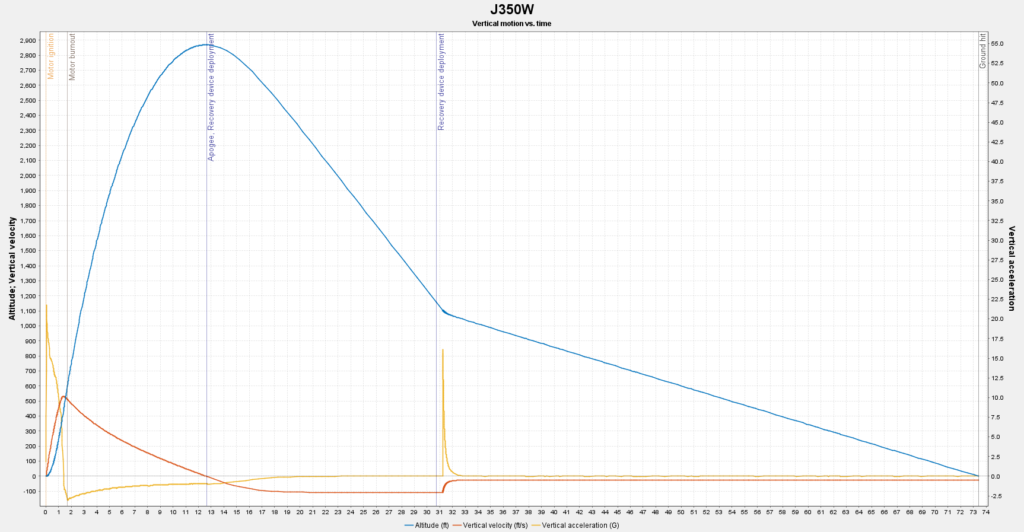

Next stop, the certification attempt on a J350W at the first Tripoli Central Virginia launch in October!

Success! Radio Flyer did me proud on Friday, 8 Nov 2024, by soaring to a little over 3500ft and recovering perfectly. Level 2 accomplished.

Being paper, Radio Flyer is showing wear and tear from multiple flights. She is now retired and on static display.